Welcome to the Future

Nuclear Grade LED Lighting. Our mission is to illuminate your nuclear project with world’s highest radiation resistant LED Fixtures. We believe in harnessing the power of our advanced technology and innovation to build a brighter future together. Join us in our journey through our Ultra radiation resistant LED Lighting technology.

Years of

Experience

36

Years in Nuclear

Business

14

Units Sold

1830

Business Partners

82

Srecko Bizjak, CEO

Rafael Kitak, R&D - electronics

Rok Bizjak, R&D - mechanics

Meet Our Team

Our team is dedicated to delivering top-tier Nuclear grade LED Lighting systems, creating value for your existing and future nuclear projects, supported by a technically skilled team with global experience in growing nuclear markets.Contact Us

The best, the fastest and most cost effective way to buy our products is to contact us directly. For general, technical and commercial questions, please use: nuclear@dito-lighting.com Our team will respond to your inquiry within one working day. We sell our products worldwide and do not rely on sales representatives, distributors, agents, or similar intermediaries. This direct approach ensures the highest quality pre- and post-sales support while guaranteeing the lowest possible prices for our products. Q: How can I buy your products? A: You can send your inquiries directly to us using the email address provided above. Q: Who designed and developed your products? A: All our products are designed and developed in Slovenia by our company. Q: Who produces your products? A: All our products are manufactured in Slovenia by our company. Q: What happened to your A-Series of LED Luminaires? A: Starting in early 2025, we decided to unify products that are similar or equal in technology and designed for comparable applications. The A-Series shares the same characteristics, materials, and technologies as the complete L-Series. As a result, the A-Series is now integrated into the L-Series under the new designation L-25. Q: What happened to your U-Series of LED Luminaires? A: Starting with the 2026, our U-50 has been upgraded to new performance level. It uses newly developed custom designed CoB LEDs together with custom designed optics. Furthermore, the housing has been completely redesigned to deliver enhanced mechanical stability, superior thermal performance, improved photo-metric properties, and a refined aesthetic. Q: What happened to your P-Series? A: Due to low market demand, we have decided to phase out the P-Series. The P-50 model will remain available for existing projects, while the P-100 will be replaced in the future with a new, more powerful underwater ultra-radiation-resistant LED luminaire. Q: Are you producing other Nuclear Grade Luminaires not based on LED technology? A: No, we exclusively design and produce LED-based luminaires for nuclear applications. Q: Does your LED driver need to be separated and shielded outside the radiation zone? Is the electronics sensitive to radiation? A: No, our LED driver (electronics) is integrated within the luminaire itself. There is no need for external boxes or shielding outside the radiation zone. This design allows for a simple replacement of legacy lighting technologies. All our luminaires are connected directly to the mains. Q: Are your products available off-the-shelf? A: No, our products are not mass-produced. Each production run is tailored to meet the specific requirements of a known customer. Q: What is the average lead time for the luminaires? A: The average lead time is approximately 16 weeks. However, this may vary depending on market conditions beyond our control. Q: What are your payment terms? A: Our standard payment term is 100% prepayment at the time of order. An order is officially accepted upon receipt of a written purchase order and the full payment. Q: Can I cancel my order? A: Unfortunately, no. All orders are NCNR (Non-Cancelable, Non-Returnable). Q: Can I get a sample for evaluation? A: Yes, we can provide a sample for evaluation. In such cases, we will request you to sign an NDA (Non-Disclosure Agreement) before proceeding. Q: Is your company ISO9001 certified? A: Yes.About Us

DITO Lighting is an independent, fully privately held company founded in 1992 by Srecko Bizjak B.Sc. (CEO) and Rafael Kitak B.Sc. (R&D). Both remain the exclusive owners of the company to this day. In 1995, we developed the world’s first multichannel, studio-grade, PC-based digital audio recorder (DAR-20). By 2000, we introduced a DSP-based, multichannel, multi- functional, fully programmable 2 Mbit/E1 digital voice announcement system to the telecommunications market. In 2007, we launched TNS++, a revolutionary railway copper wire transmission system. TNS++ remains the world’s only DSP-based, fully programmable, high- performance tone communication system designed for use over standard railway copper wire cables. This system is widely used for communication between relay- based safety-critical railway equipment worldwide. In 2009, we expanded into LED lighting development, starting with street and heavy-duty industrial lighting products. By 2013, we entered the nuclear LED lighting business, focusing on high-performance solutions for demanding environments. Our mission is to deliver the highest radiation-hardened LED lighting systems in the nuclear industry, offering unmatched LOCA scenario compatibility and the best "all-in-one" nuclear-grade LED lighting solutions for both air and underwater applications.

01

Top Reasons to Choose Us

Your nuclear project deserves the best Lighting technology available on the market

today. Very lightweight, easy to handle, reliable, proven, tested and certified. Our

Nuclear Grade LED Lighting.

Gamma TID >500 kGy

World’s highest radiation resistance in

LED Lighting industry. Up to 2 MGy

gamma TID resistance can be ordered

as an option.

02

03

04

Complete Range

From our top range H-Series for

harshest nuclear applications to the L-

Series, simplified, cost effective, yet still

high performance LED Fixtures.

Made in Slovenia

Our products are created, developed

and produced in our company in

Slovenia. Complete production process

is controlled by us.

All-in-one

Complete electronics is built into the

Fixture itself. No external boxes are

needed elsewhere outside the

radiation zone.

LED Lighting for Typical NPP Applications

LED Lighting for General Nuclear Applications

Who We Are

How We Sell

Head Office

Postal address: DITO Lighting d.o.o. Gorica pri Slivnici 144 3263 Gorica pri Slivnici SloveniaCompany Details

Name of the Company: DITO Lighting d.o.o. CRN: 5629802000 VAT ID/EORI: SI59718587 REX Number: SIREX75 DUNS Number: 499266914 NCAGE: 1576Q NACE: C27.400 Manufacture of electrical lighting equipment

Common properties

• > 500 kGy gamma TID as standard, 2 MGy TID option available, • IP68/IK08 ingress protection, • “all-in-one” solution, no external boxes are needed elsewhere outside the radiation zone, • direct connection to the mains, • full stainless steel design, • no aluminum, zinc, glass or screws, fully riveted, • no glass, PC, PMMA or other plastics, • browning-proof and shatter-proof optics, • full set of test reports and certificates, including radiation resistance, LOCA, seismic, ILRT, CE, CB, FCC.H-Series members

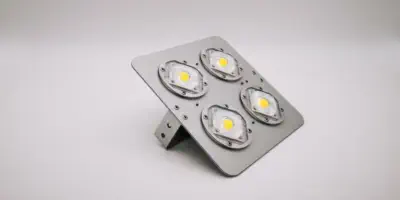

H-100

Powerful 100 W LED Luminaire designed for High-Bay applications. Typical application is lighting around the polar crane inside the containment of the NPP.H-50

Our bestseller. Mid-power, 50 W LED Luminaire designed for Low-Bay applications inside the containment of the NPP.H-15

Low-power 15 Watt H-Series member (formerly known as E-15) for general lighting in small rooms or as an Emergency lighting product.

the H-Series.

The H-Series represents our most advanced line of Ultra Radiation Resistant, Nuclear

Grade LED Luminaires.

Our flagship series. Our bestseller. Designed without compromises for harshest nuclear

environments.

At the heart of our success lies our proprietary ultra radiation resistant LED driver, a

breakthrough innovation integrated across all our products. Unlike traditional solutions,

our design eliminates the need for external boxes outside the radiation zone,

streamlining deployment and operation.

This achievement is the result of years of relentless development and hundreds of

irradiation tests.

The H-Series is constructed from high-quality stainless steel, ensuring durability,

reliability and compliance with global NPP requirements for applications within the

reactor building, commonly referred to as "controlled areas" or "orange/red zones."

the L-Series.

The L-Series represents our latest generation of high-radiation, high-temperature-

resistant LED luminaires, tailored for general cost-sensitive nuclear applications.

Our design goal has always been to deliver high-performance, nuclear-grade LED

luminaires at an affordable price, making advanced technology accessible to the

industry.

Recently upgraded L-Series has improved photo-metrical and thermal performance,

resulting in higher reliability and longer expected lifetime.

Distinctive new safety features have been added. The Safe mode in case of abnormal

input voltage conditions and Thermal protection in case of excessive ambient

temperature. Both are designed to protect the luminaire from overheating or even

complete failure.

Common properties

• > 200 kGy gamma TID as standard, 2 MGy TID option available, • IP66/IK08 ingress protection, • “all-in-one” solution, no external boxes are needed elsewhere outside the radiation zone, • direct connection to the mains, • high grade anodized aluminum design, • no glass, PC, PMMA or other plastics, • browning-proof and shatter-proof optics, • different optics types available, • full set of test reports and certificates, including radiation resistance, CE, CB.L-Series members

L-100

Powerful 100 W LED Luminaire designed for High-Bay applications. The best choice for machine halls in typical NPP.L-50

Mid-power, 50 W LED Luminaire designed for general Low-Bay nuclear applications. Ideal choice for hot cells and accelerators.L-25

Low-power 25 Watt L-Series member for general lighting in smaller rooms, tunnels etc. Our most affordable nuclear grade LED Luminaire.

the N-Series.

The N-Series represents latest addition to our comprehensive line of Ultra Radiation

Resistant, Nuclear Grade LED Luminaires, designed predominately for Lighting inside the

containment of the Nuclear Power Plants.

The N-Series is based on our premium H-Series, inheriting many properties from our

top-tier radiation resistant LED system. Some advanced properties of the H-Series have

been omitted. The result is affordable cost/performance optimized series of Nuclear

Grade LED Luminaires, designed for cost sensitive NPP projects.

The N-Series uses new, custom designed, high performance, over-sized, thermally

optimized CoBs and newly developed custom optics. The Ultra Radiation Resistant LED

driver remains the same as in all our products.

The whole line has three members. A High-power High-Bay 150W “flood-style”, mid-

power Low-Bay 50W “linear-style” and the smallest low-power “linear-style” 30W LED

Luminaire.

Common properties

• > 200 kGy gamma TID as standard, 2 MGy TID option available, • IP65/IK08 ingress protection, • “all-in-one” solution, no external boxes are needed elsewhere outside the radiation zone, • direct connection to the mains, • full stainless steel design, • no aluminum, zinc, glass or screws, fully riveted, • no glass, PC, PMMA or other plastics, • browning-proof and shatter-proof optics, • test reports and certificates include radiation resistance, ILRT, CE and CB.

N-Series members

N-150

Powerful 150 W “Floodlight-style” LED Luminaire designed for High-Bay applications. Typical application is lighting around the polar crane inside the containment of the NPP.N-50

Mid-power, 50 W “Linear-style” LED Luminaire designed for Low-Bay applications inside the containment of the NPP.N-30

Low-power “Linear-style” 30 Watt N-Series member designed for illumination of smaller cubicles inside the typical NPP.

LED Lighting for Typical NPP Applications

LED Lighting for General Nuclear Applications

the U-Series.

The new and upgraded U-50 is a very compact and slim ultra radiation resistant, 50 Watt,

nuclear grade LED Luminaire. The design enables the U-50 to be inserted through the

circular opening of 74 mm - the access point of many hot-cell designs worldwide.

The U-50 is engineered for demanding nuclear environments outside the containment of

the NPPs, where high levels of gamma and neutron radiation are present.

U-50 now features custom CoB LEDs and a bespoke optic, both newly engineered.

Furthermore, the housing has been completely redesigned to deliver enhanced

mechanical stability, superior thermal performance, improved photo-metric properties,

and a refined aesthetic.

At its core, the U-50 retains the same proven, tested, and certified radiation-resistant

technology trusted across our entire product line.

U-50 properties

• > 500 kGy gamma TID as standard, 2 MGy TID option available, • “all-in-one” solution, no external boxes are needed elsewhere outside the radiation zone, • direct connection to the mains, • high grade anodized aluminum design, • no glass, PC, PMMA or other plastics, • browning-proof and shatter-proof optics, • custom designed holders available on request, • full set of test reports and certificates, including radiation resistance, CE, CB.

© Copyright 2026 DITO Lighting d.o.o. | Last Update March 2026

Welcome to the Future

Nuclear Grade LED Lighting. Our mission is to illuminate your nuclear project with world’s highest radiation resistant LED Fixtures. We believe in harnessing the power of our advanced technology and innovation to build a brighter future together. Join us in our journey through our Ultra radiation resistant LED Lighting technology.

Years of

Experience

36

Years in Nuclear

Business

14

Units Sold

1830

Business Partners

82

Srecko Bizjak, CEO

Rafael Kitak, R&D - electronics

Rok Bizjak, R&D - mechanics

Meet Our Team

Our team is dedicated to delivering top-tier Nuclear grade LED Lighting systems, creating value for your existing and future nuclear projects, supported by a technically skilled team with global experience in growing nuclear markets.Contact Us

The best, the fastest and most cost effective way to buy our products is to contact us directly. For general, technical and commercial questions, please use: nuclear@dito-lighting.com Our team will respond to your inquiry within one working day. We sell our products worldwide and do not rely on sales representatives, distributors, agents, or similar intermediaries. This direct approach ensures the highest quality pre- and post-sales support while guaranteeing the lowest possible prices for our products. Q: How can I buy your products? A: You can send your inquiries directly to us using the email address provided above. Q: Who designed and developed your products? A: All our products are designed and developed in Slovenia by our company. Q: Who produces your products? A: All our products are manufactured in Slovenia by our company. Q: What happened to your A-Series of LED Luminaires? A: Starting in early 2025, we decided to unify products that are similar or equal in technology and designed for comparable applications. The A-Series shares the same characteristics, materials, and technologies as the complete L-Series. As a result, the A-Series is now integrated into the L-Series under the new designation L-25. Q: What happened to your U-Series of LED Luminaires? A: Starting with the 2026, our U-50 has been upgraded to new performance level. It uses newly developed custom designed CoB LEDs together with custom designed optics. Furthermore, the housing has been completely redesigned to deliver enhanced mechanical stability, superior thermal performance, improved photo-metric properties, and a refined aesthetic. Q: What happened to your P-Series? A: Due to low market demand, we have decided to phase out the P-Series. The P-50 model will remain available for existing projects, while the P-100 will be replaced in the future with a new, more powerful underwater ultra-radiation-resistant LED luminaire. Q: Are you producing other Nuclear Grade Luminaires not based on LED technology? A: No, we exclusively design and produce LED-based luminaires for nuclear applications. Q: Does your LED driver need to be separated and shielded outside the radiation zone? Is the electronics sensitive to radiation? A: No, our LED driver (electronics) is integrated within the luminaire itself. There is no need for external boxes or shielding outside the radiation zone. This design allows for a simple replacement of legacy lighting technologies. All our luminaires are connected directly to the mains. Q: Are your products available off-the-shelf? A: No, our products are not mass-produced. Each production run is tailored to meet the specific requirements of a known customer. Q: What is the average lead time for the luminaires? A: The average lead time is approximately 16 weeks. However, this may vary depending on market conditions beyond our control. Q: What are your payment terms? A: Our standard payment term is 100% prepayment at the time of order. An order is officially accepted upon receipt of a written purchase order and the full payment. Q: Can I cancel my order? A: Unfortunately, no. All orders are NCNR (Non- Cancelable, Non-Returnable). Q: Can I get a sample for evaluation? A: Yes, we can provide a sample for evaluation. In such cases, we will request you to sign an NDA (Non- Disclosure Agreement) before proceeding. Q: Is your company ISO9001 certified? A: Yes.About Us

DITO Lighting is an independent, fully privately held company founded in 1992 by Srecko Bizjak B.Sc. (CEO) and Rafael Kitak B.Sc. (R&D). Both remain the exclusive owners of the company to this day. In 1995, we developed the world’s first multichannel, studio-grade, PC-based digital audio recorder (DAR- 20). By 2000, we introduced a DSP-based, multichannel, multi-functional, fully programmable 2 Mbit/E1 digital voice announcement system to the telecommunications market. In 2007, we launched TNS++, a revolutionary railway copper wire transmission system. TNS++ remains the world’s only DSP-based, fully programmable, high- performance tone communication system designed for use over standard railway copper wire cables. This system is widely used for communication between relay-based safety-critical railway equipment worldwide. In 2009, we expanded into LED lighting development, starting with street and heavy-duty industrial lighting products. By 2013, we entered the nuclear LED lighting business, focusing on high-performance solutions for demanding environments. Our mission is to deliver the highest radiation- hardened LED lighting systems in the nuclear industry, offering unmatched LOCA scenario compatibility and the best "all-in-one" nuclear-grade LED lighting solutions for both air and underwater applications.

Top Reasons to

Choose Us

Your nuclear project deserves the best

Lighting technology available on the

market today. Very lightweight, easy to

handle, reliable, proven, tested and

certified. Our Nuclear Grade LED Lighting.

01

02

03

04

Complete Range

From our top range H-Series for

harshest nuclear applications to the L-

Series, simplified, cost effective, yet still

high performance LED Fixtures.

Gamma TID >500 kGy

World’s highest radiation resistance in

LED Lighting industry. Up to 2 MGy

gamma TID resistance can be ordered

as an option.

All-in-one

Complete electronics is built into the

Fixture itself. No external boxes are

needed elsewhere outside the

radiation zone.

Made in Slovenia

Our products are created, developed

and produced in our company in

Slovenia. Complete production process

is controlled by us.

LED Lighting for

Typical NPP

Applications

LED Lighting for

General Nuclear

Applications

Who We Are

How We Sell

Head Office

Postal address: DITO Lighting d.o.o. Gorica pri Slivnici 144 3263 Gorica pri Slivnici SloveniaCompany Details

Name of the Company: DITO Lighting d.o.o. CRN: 5629802000 VAT ID/EORI: SI59718587 REX Number: SIREX75 DUNS Number: 499266914 NCAGE: 1576Q NACE: C27.400 Manufacture of electrical lighting equipment

Common properties

• > 500 kGy gamma TID as standard, 2 MGy TID option available, • IP68/IK08 ingress protection, • “all-in-one” solution, no external boxes are needed elsewhere outside the radiation zone, • direct connection to the mains, • full stainless steel design, • no aluminum, zinc, glass or screws, fully riveted, • no glass, PC, PMMA or other plastics, • browning-proof and shatter-proof optics, • full set of test reports and certificates, including radiation resistance, LOCA, seismic, ILRT, CE, CB, FCC.H-Series members

H-100

Powerful 100 W LED Luminaire designed for High-Bay applications. Typical application is lighting around the polar crane inside the containment of the NPP.H-50

Our bestseller. Mid-power, 50 W LED Luminaire designed for Low-Bay applications inside the containment of the NPP.H-15

Low-power 15 Watt H-Series member (formerly known as E-15) for general lighting in small rooms or as an Emergency lighting product.

the H-Series.

The H-Series represents our most advanced line of

Ultra Radiation Resistant, Nuclear Grade LED

Luminaires.

Our flagship series. Our bestseller. Designed without

compromises for harshest nuclear environments.

At the heart of our success lies our proprietary ultra

radiation resistant LED driver, a breakthrough

innovation integrated across all our products. Unlike

traditional solutions, our design eliminates the need

for external boxes outside the radiation zone,

streamlining deployment and operation.

This achievement is the result of years of relentless

development and hundreds of irradiation tests.

The H-Series is constructed from high-quality

stainless steel, ensuring durability, reliability and

compliance with global NPP requirements for

applications within the reactor building, commonly

referred to as "controlled areas" or "orange/red

zones."

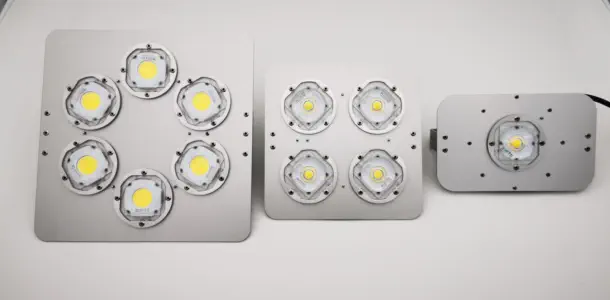

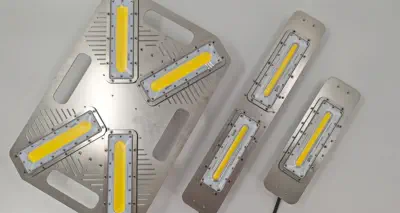

the L-Series.

The L-Series represents our latest generation of high-

radiation, high-temperature-resistant LED luminaires,

tailored for general cost-sensitive nuclear

applications.

Our design goal has always been to deliver high-

performance, nuclear-grade LED luminaires at an

affordable price, making advanced technology

accessible to the industry.

Recently upgraded L-Series has improved photo-

metrical and thermal performance, resulting in

higher reliability and longer expected lifetime.

Distinctive new safety features have been added. The

Safe mode in case of abnormal input voltage

conditions and Thermal protection in case of

excessive ambient temperature. Both are designed to

protect the luminaire from overheating or even

complete failure.

Common properties

• > 200 kGy gamma TID as standard, 2 MGy TID option available, • IP66/IK08 ingress protection, • “all-in-one” solution, no external boxes are needed elsewhere outside the radiation zone, • direct connection to the mains, • high grade anodized aluminum design, • no glass, PC, PMMA or other plastics, • browning-proof and shatter-proof optics, • different optics types available, • full set of test reports and certificates, including radiation resistance, CE, CB.L-Series members

L-100

Powerful 100 W LED Luminaire designed for High-Bay applications. The best choice for machine halls in typical NPP.L-50

Mid-power, 50 W LED Luminaire designed for general Low-Bay nuclear applications. Ideal choice for hot cells and accelerators.L-25

Low-power 25 Watt L-Series member for general lighting in smaller rooms, tunnels etc. Our most affordable nuclear grade LED Luminaire.

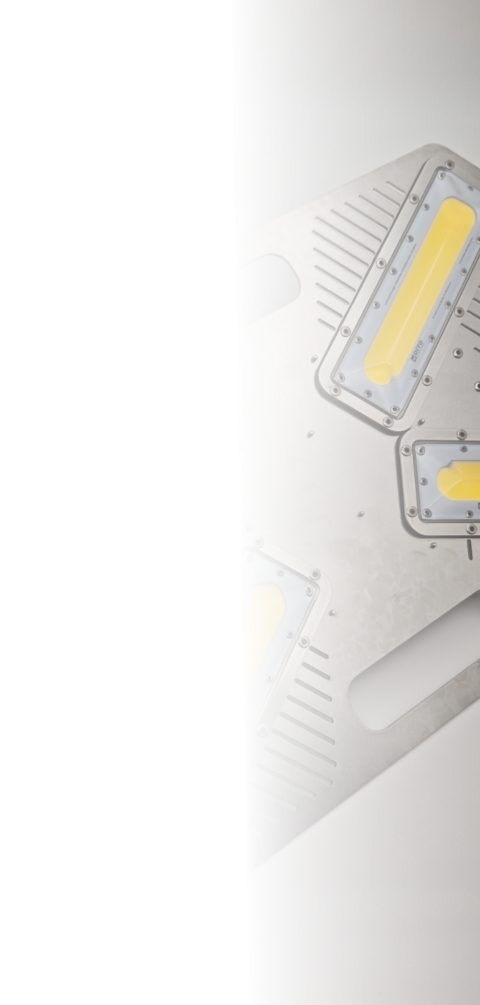

the N-Series.

The N-Series represents latest addition to our

comprehensive line of Ultra Radiation Resistant,

Nuclear Grade LED Luminaires, designed

predominately for Lighting inside the containment of

the Nuclear Power Plants.

The N-Series is based on our premium H-Series,

inheriting many properties from our top-tier

radiation resistant LED system. Some advanced

properties of the H-Series have been omitted. The

result is affordable cost/performance optimized

series of Nuclear Grade LED Luminaires, designed for

cost sensitive NPP projects.

The N-Series uses new, custom designed, high

performance, over-sized, thermally optimized CoBs

and newly developed custom optics. The Ultra

Radiation Resistant LED driver remains the same as

in all our products.

The whole line has three members. A High-power

High-Bay 150W “flood-style”, mid-power Low-Bay 50W

“linear-style” and the smallest low-power “linear-style”

30W LED Luminaire.

Common properties

• > 200 kGy gamma TID as standard, 2 MGy TID option available, • IP65/IK08 ingress protection, • “all-in-one” solution, no external boxes are needed elsewhere outside the radiation zone, • direct connection to the mains, • full stainless steel design, • no aluminum, zinc, glass or screws, fully riveted, • no glass, PC, PMMA or other plastics, • browning-proof and shatter-proof optics, • test reports and certificates include radiation resistance, ILRT, CE and CB.

N-Series members

N-150

Powerful 150 W “Floodlight-style” LED Luminaire designed for High-Bay applications. Typical application is lighting around the polar crane inside the containment of the NPP.N-50

Mid-power, 50 W “Linear-style” LED Luminaire designed for Low-Bay applications inside the containment of the NPP.N-30

Low-power “Linear-style” 30 Watt N-Series member designed for illumination of smaller cubicles inside the typical NPP.

LED Lighting for

Typical NPP

Applications

LED Lighting for

General Nuclear

Applications

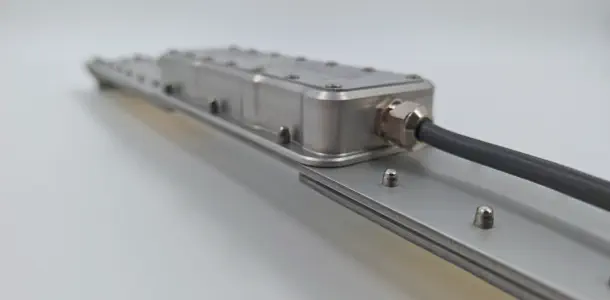

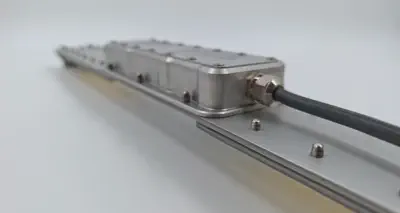

the U-Series.

The new and upgraded U-50 is a very compact and

slim ultra radiation resistant, 50 Watt, nuclear grade

LED Luminaire. The design enables the U-50 to be

inserted through the circular opening of 74 mm - the

access point of many hot-cell designs worldwide.

The U-50 is engineered for demanding nuclear

environments outside the containment of the NPPs,

where high levels of gamma and neutron radiation

are present.

U-50 now features custom CoB LEDs and a bespoke

optic, both newly engineered.

Furthermore, the housing has been completely

redesigned to deliver enhanced mechanical stability,

superior thermal performance, improved photo-

metric properties, and a refined aesthetic.

At its core, the U-50 retains the same proven, tested,

and certified radiation-resistant technology trusted

across our entire product line.

U-50 properties

• > 500 kGy gamma TID as standard, 2 MGy TID option available, • “all-in-one” solution, no external boxes are needed elsewhere outside the radiation zone, • direct connection to the mains, • high grade anodized aluminum design, • no glass, PC, PMMA or other plastics, • browning-proof and shatter-proof optics, • custom designed holders available on request, • full set of test reports and certificates, including radiation resistance, CE, CB.

© Copyright 2026 DITO Lighting d.o.o. | Last Update

March 2026